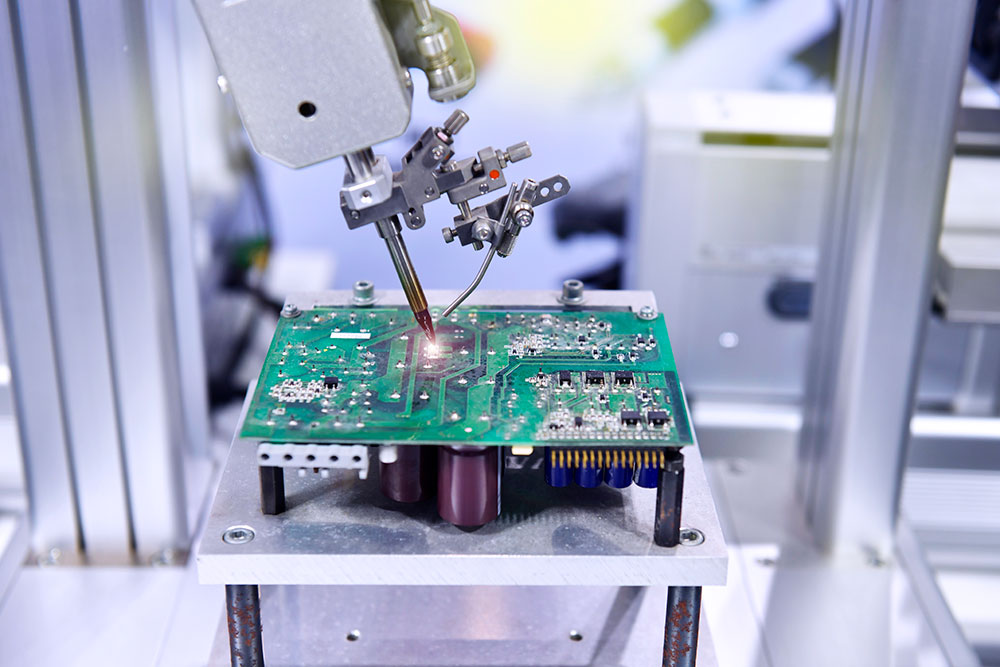

PCB Drill

TAC-ON® layer with high hardness and smooth surface greatly reduce the wear between the drill and the board, does not produce tangle; significantly improve the life span and process capability of the drill, reduce replacement frequency and production downtime.

Explore more