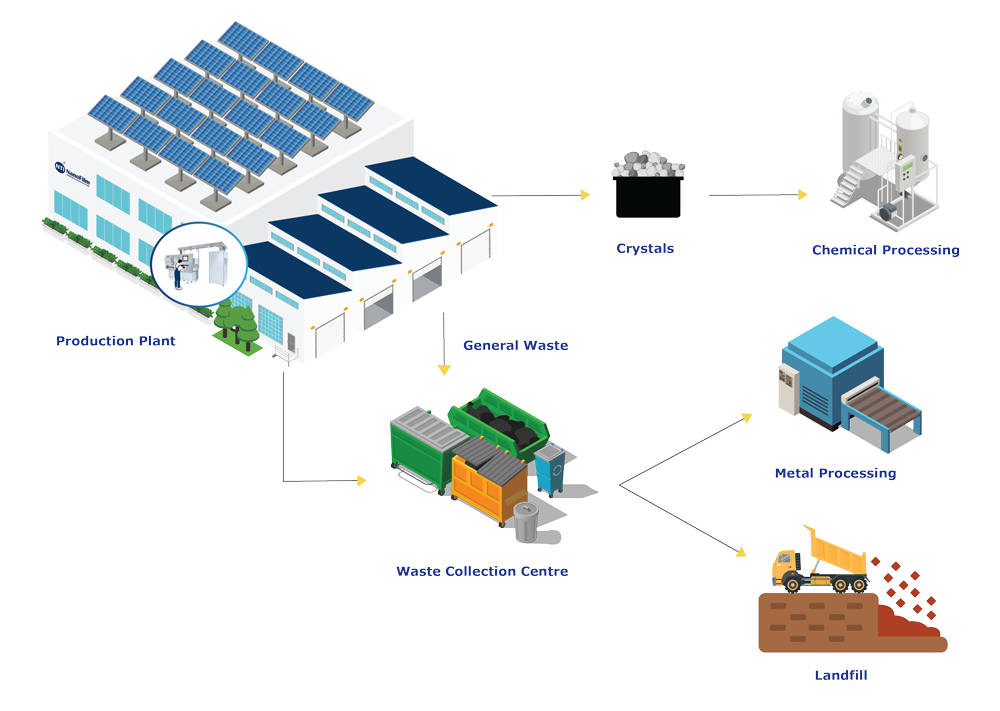

In the realm of industrial production, the efficient management of waste has emerged as an indispensable pillar of sustainability and responsible business practice. As the global production landscape continues to grow, Nanofilm has taken the initiative to address waste generation and disposal with utmost diligence. Considering that the volume of waste materials generated from our production process is not significant and mostly non-hazardous, we will continuously improve our waste handling and its management to protect the environment as to minimise the negative environmental impacts.

Nanofilm’s key process of its largest business units is the vacuum coating process, and we specialise in Physical Vapour Deposition (PVD) and Filtered Cathodic Vacuum Arc (FCVA) coatings. These coatings are categorised as vacuum coatings and they transfer materials from a target onto a substrate directly and physically without waste and toxic emissions. Upholding with these technologies, very little waste was generated as by-products of the coating process.

Our green plating technology offers environmentally sustainable anti-corrosion vacuum coating with high conductivity, as Nanofilm continue to innovate for sustainability and be a driver of change, striking a balance between maximising innovation while minimizing hazards to the people and environment. It stands out as an emission-free plating process which eliminates heavy metal contaminants discharge caused by electroplating, resulting in no hazardous waste being produced.

As part of our unwavering dedication to advancing sustainability and environmentally responsible business practices, we are committed to consistently improving our waste management system. We are actively exploring methods to reduce waste generation and promote the circular utilisation of materials, aligning with our commitment to a greener and more sustainable business.