-

High-Temp Resistance

Protects lead frames during reflow/bake. Reduces sticking, cleaning cycles, and downtime.

-

Bonding Yield Protection

Extends wire bond tool life. Improves adhesion and reduces maintenance.

-

ESD Control

Prevents static buildup on solder ball templates for clean, precise placement

-

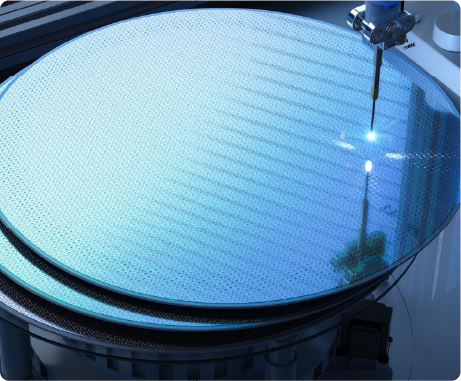

Wear Resistance

Enhances lapping carrier durability. Cuts replacements and ensures wafer consistency.

-

Contamination Control

Coats ceramic parts without metal layers. Minimizes particle shedding and wear

-

Chemical Protection

Shields elastomer seals from plasma and corrosive gases. Extends life and chamber cleanliness.

Thin-Film Coating for Next-Gen Semiconductor Manufacturing

As semiconductor devices become more advanced, manufacturers face growing challenges in precision, durability, contamination control, and cost efficiency. Traditional coatings often fall short in addressing equipment wear, electrostatic discharge (ESD), and surface degradation, leading to higher maintenance costs, reduced yield, and process inefficiencies.

NTI Nanofilm offers cutting-edge DLC (Diamond-Like Carbon) and nanocomposite coatings powered by our proprietary Filtered Cathodic Vacuum Arc (FCVA) technology. Our coatings provide exceptional hardness, ultra-low friction, superior adhesion, and enhanced thermal and chemical resistance—meeting the demanding needs of semiconductor production.