Conductive Corrosion Resistant

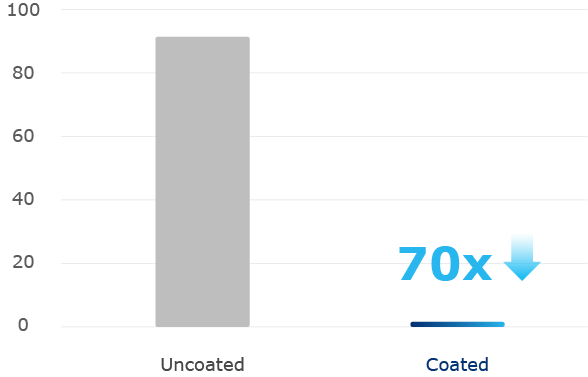

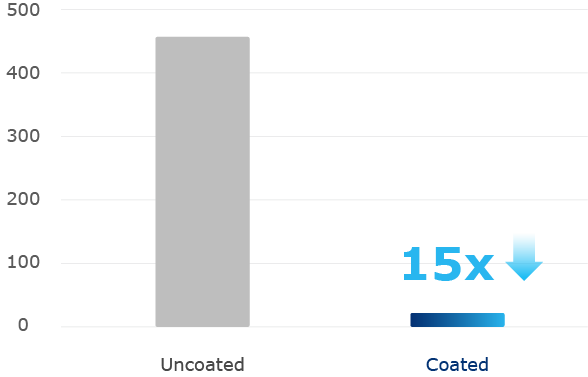

Our conductive corrosion resistant solution deposits non hydrogen carbon and metal sources using environmentally friendly patented FCVA and sputtering technology that forms a corrosion resistance layer on key electrical components made of Stainless Steel, Aluminium and Red Copper, that greatly reduce corrosion current, extend product lifespan and enhance products’ performance.

This is an alternative solution to electroplating that protect our planet.

Get In Touch