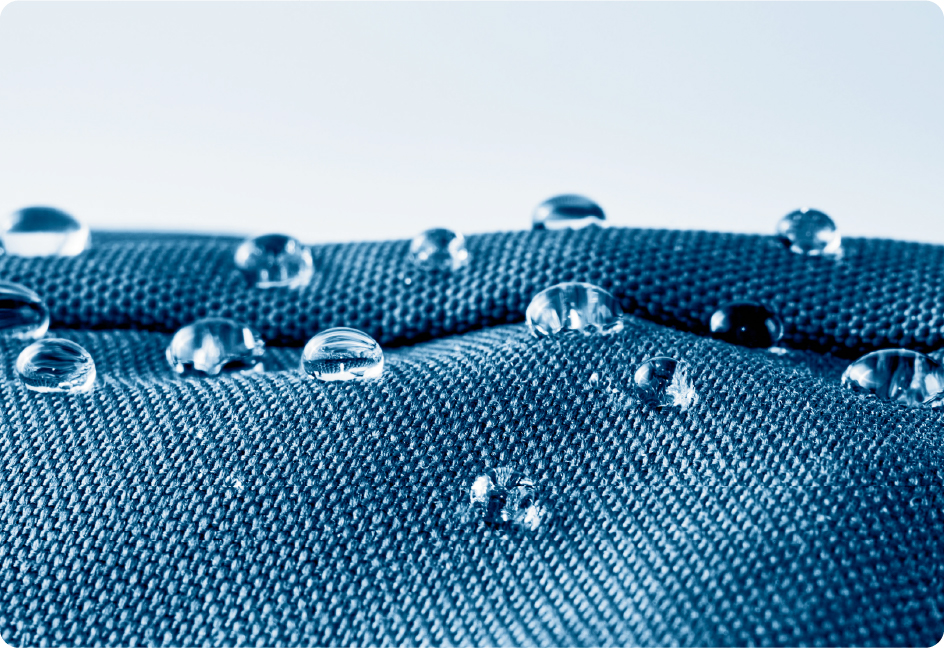

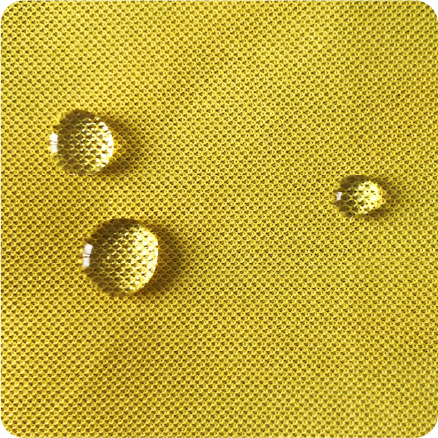

Provide Excellent Hydrophobicity For Your Product

Our hydrophobic solution deposits a nano layer of material on textile, polymer and metal using PECVD and FCVA technology. The layer reduces surface energy and significantly increases water’s contact angle with the coated materials and turn its surface hydrophobic to prevent problems caused by humidity and water leakage, hence extend device’s lifespan.

Compared to traditional hydrophobic treatment, our technology allows flexible batch-size processing.

Get In Touch