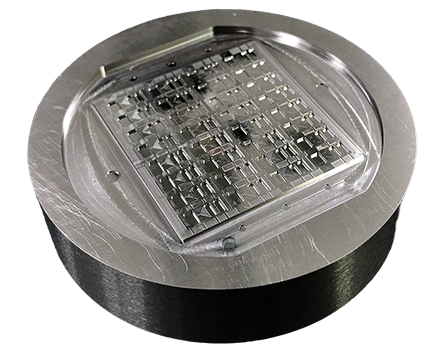

Prevent Micro Lens Mould Stickiness with MiCC®

Micro lens made of plastic formed through plastic injection mould, can get stuck to the mould during processing. In addition, the injection pressure, constant heating and cooling can also damage the mould, which surface usually has low roughness and high reflectiveness. These result in defects and decreased productivity.

Extend Micro Lens Mould lifespan and maintain its precision feature with MiCC® coating

| Coating |

MiCC® |

| Coating Material |

CrN |

| Hardness (Gpa) |

~ 20Gpa |

| Coating Thickness |

~ 2µm |

The MiCC® coating forms a protective layer on the surface of the mould with low surface energy and low friction coefficient and gives good non-stick for sliding behavior on the tool surface. The high hardness property also allows the mould to not be easily deformed or scratched during cleaning process. This greatly extend the mould’s lifespan, maintain its precision features and thus improve productivity and yield rate.

Extend Mould’s Life Span

Do you have any question and want to know more about our services? We will be glad to support you.