-

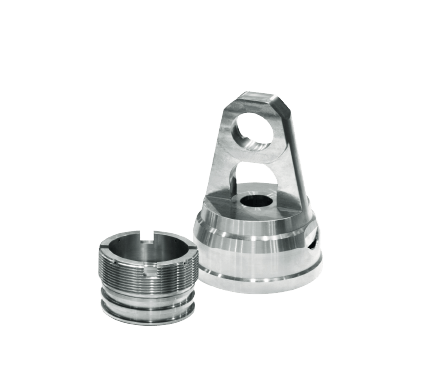

Adhesive Wear

-

Abrasive Tear

-

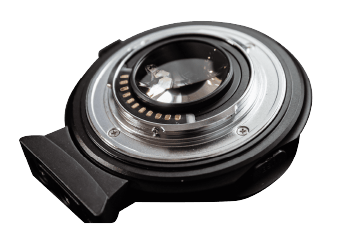

Corrosion

-

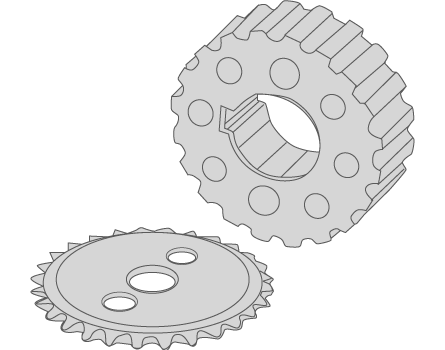

Surface Fatigue

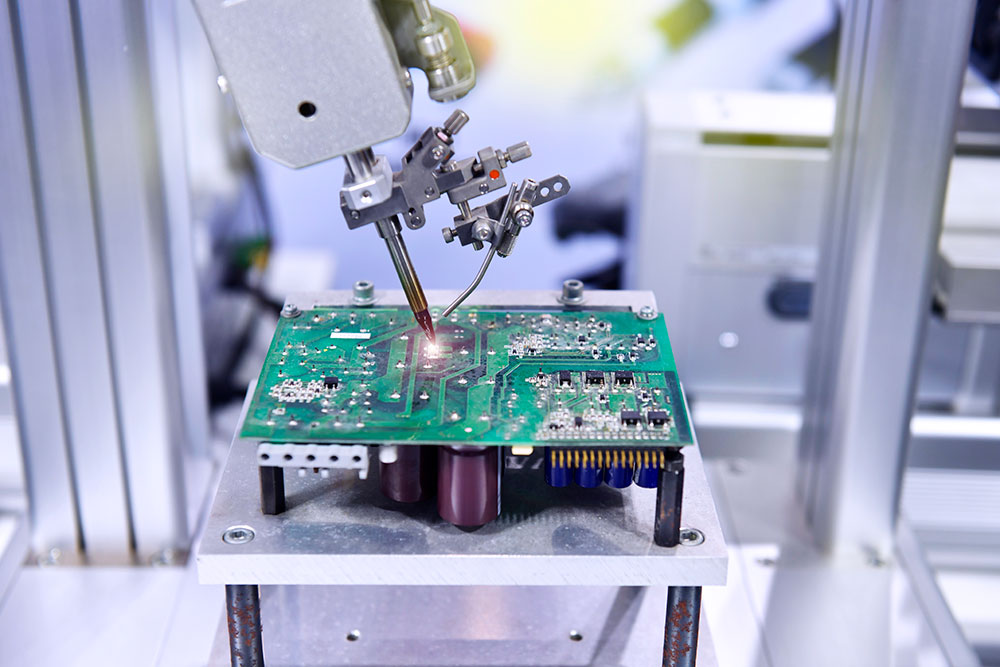

Revolutionary Wear Resistant Solution

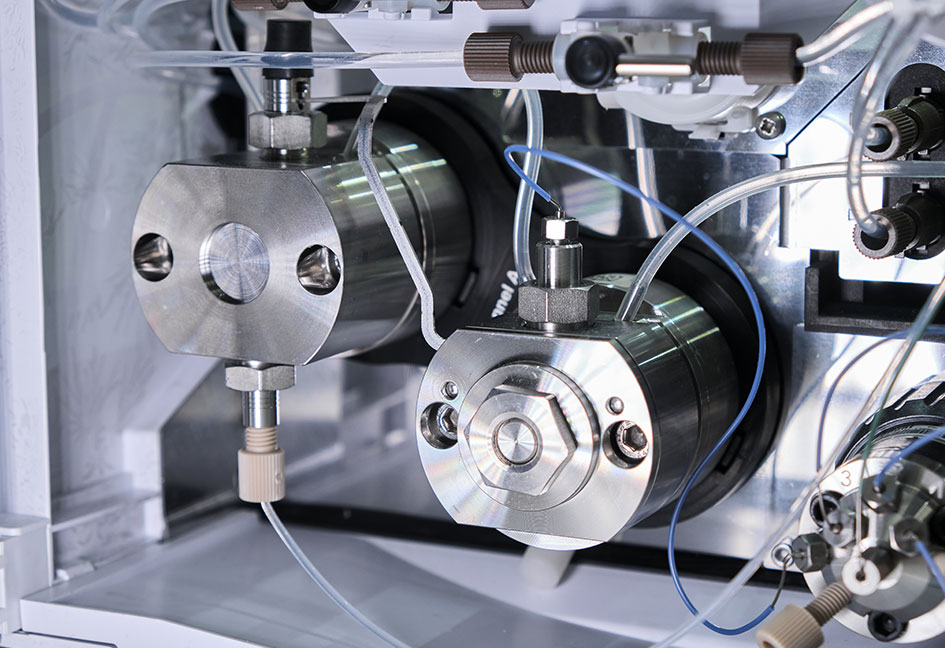

TAC-ON® and i-TAC® deposit non-hydrogenated carbon and other composite materials using patented FCVA technology at low temperature with superior quality compared to normal DLC that reduce wear of parts and extend product life span with smooth operation across different industries, including Electronics, Printing and Imaging, Semi-Conductor, Precision Engineering, Medical Devices, Textile Manufacturing...

Get In Touch