- Semiconductor

- Tool and Die

- Optics

Feel free to contact us to customise your product solution. Contact Us

Feel free to contact us to customise your product solution. Contact Us

Feel free to contact us to customise your product solution. Contact Us

MiCC®(Nano-Crystalline Chrome Nitride Ceramic Coating) solution deposits chromium nitride using patented FCVA technology that produces better hardness, lower friction coefficient and thinner film. Compared to conventional CrN coating, MiCC® reduce stickiness of components and moulds, facilitates smooth release, extending lifespan of moulds and parts and improve productivity.

Get In Touch

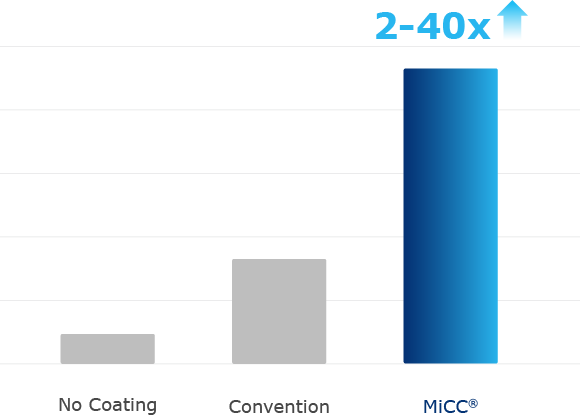

MiCC® can extend tool and die life 2-40 times compared to No Coating and Convention.

MiCC® can extend tool and die life 2-40 times compared to No Coating and Convention.

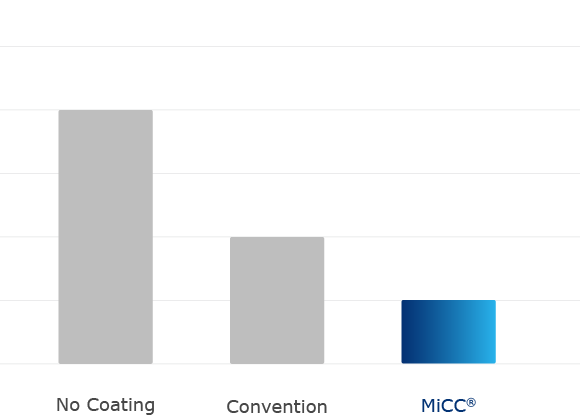

MiCC® can effectively reduce the defective rate of tools and moulds.

MiCC® can effectively reduce the defective rate of tools and moulds.

| MiCC® | Conventional CrN | Conventional H-Cr | |

| Hardness (Gpa) | ~ 20 | ~ 15 | 8 ~ 10 |

| Friction Coefficient | 0.1 ~ 0.2 | 0.3 ~ 0.4 | 0.5 ~ 0.6 |

| Typical Thickness (µm) | ~ 2 | 2 ~ 5 | ~ 5 |

| Critical Load | Excellent | Good | Good |

Feel free to contact us to customise your product solution. Contact Us

Feel free to contact us to customise your product solution. Contact Us

Feel free to contact us to customise your product solution. Contact Us

What are the main advantages of Nanofilm coating?

What kind of coating solutions you provide?

Our coating solutions consist of decorative coating with scratch resistant, tribological wear resistant coating, conductive corrosion resistant coating, non-stick coating, electrical magnetic field insulation, hydrophobic and anti-reflective coating. Click here to find out more.

What are the main applications of your coating?

Our coating solutions resolve mission critical tribological, conductive and surface energy issues for customers in consumer electronics, automotive, semiconductor, hydrogen energy, optical, life science, tool and die and other general industries (textile, printing). Click here to find out more.

What substates can your solutions coat?

We can coat a wide range of substrates including metal (stainless steel, copper, aluminium), alloy, polymer (plastic), and ceramics.

What is the substrate maximum size?

Where are your coating centres?

What is your lead time?

Lead time varies depending on your specification. Please get in touch to learn more.

Do you have any question and want to know more about our services? We will be glad to support you.